No products

Categories

- Fashion Accessories

- Clothing

- Beauty & Lifestyle

-

Hi-Tech & Lifestyle

- Gaming

-

Case

- iPhone 11 Pro

- iPhone 11 Pro Max

- iPhone 11

- iPhone X / XS

- iPhone XS Max

- Samsung S10 / S10+ / S10e

- Huawei P30 / P30 Pro / P30 Lite

- Huawei P20 / P20 Pro / P20 Lite

- iPhone XR

- Samsung S9

- Samsung S9+

- iPhone 8 / 7

- iPhone 8 Plus / 7 Plus

- Samsung S8

- Samsung S8+

- Samsung S7

- Samsung S7 Edge

- iPhone 6 / 6 s

- iPhone 6 Plus / 6 s Plus

- iPhone 5 / SE

- Skin

- Audio

- Smart Home

- Drones & Hoverboard

- Photo & Video

- Desk Supplies

- Accessories

- Games

- Beverages

- Food

- Home

- Jewelry

- Luxury

- Travel

- Art

- Footwear

- Vintage Fashion

- Restaurants

- Sport

- Animals

- Gift Ideas

- Kidswear

Extra

Hublot

Fusion in Watchmaking

Craftmanship - Introducing - The Stories Behind The Design, Innovation and Craft

Manufacture - Precision Craft - Discover The Immaculate Creation of Hublot Timepieces

A place where tradition and innovation coexist, the Hublot design workshop is a place where watchmaking is done differently, the “Art of Fusion” way.

Covering a wide range of professions and manufacturing techniques involved in the art and science of watchmaking, Hublot employs different methods of this centuries-old craft to accommodate the latest in materials and fabrication techniques as well as the most traditional forms of handwork, all under one roof. It is this flexibility in manufacturing that allows Hublot to remain at the helm of innovation in watchmaking and produce unique and cutting-edge timepieces.

« We place great value in our innovative technological manufacturing processes. » Ricardo Guadalupe - Chief Executive Officer

The Hublot design workshop possesses all the necessary know-how and infrastructure to make the future of watchmaking a reality today.

From the production of the micro-components in movements to the construction of case parts, the synergy that exists in the Hublot design workshop has allowed for such breakthrough creations as the Unico chronograph movement and proprietary materials like Magic Gold, as well as truly revolutionary designs in both case and movement construction.

Movements - In Perfect Time - Pioneers of The Most Innovative Movements

The culmination of any integrated watch manufacturer is to be able to equip its watches with exclusive movements made within its own ateliers. From self-winding chronograph movements to striking high-complication pieces and unique never-before-seen horological concepts, the traditional art of watchmaking is reinvented in a 21st century context within the walls of the Hublot manufacture.

With its own Metallurgy & Materials laboratory working closely with the Research & Development department, the possibilities for innovation are only limited by how far one’s imagination can go.

At the Hublot design workshop, such ideas of imagination are brought to fruition through the synergy that exists between the various experts and departments.

Requiring over 2 years of research and development, the in-house Unico movement is in a league of its own. Consisting of no less than 330 individually assembled components, the original Unico movement features an integrated fly back chronograph with a column-wheel mechanism positioned on the dial side of the movement.

Something of a rarity in the world of haute horlogerie. From the idea and the first pencil stroke, Hublot’s micro-technology engineers and designers put together a dossier of plans that will be used to manufacture the components of a new movement.

Materials - The Art of Fusion - Ground Breaking Innovation, Changing The World of Horology

Whether it’s improving on traditional precious metal alloys to improve their performance and aesthetics or conjuring entirely new and groundbreaking composites, the vast world of materials is at the very heart of Hublot’s “Art of Fusion” philosophy.

From traditional gold alloys to Magic Gold, from stainless steel to light and durable carbon fiber, the number of materials and possible combinations Hublot offers are truly endless.

When we talk about the use of ceramics in watch design, this does not of course mean clay-based pottery, but zirconium oxide sintered at very high temperatures. Hublot uses this high-tech ceramic, with its superior hardness and solidity, for the case and the bezel of certain watch models.

Magic Gold

Unique and proprietary to Hublot, Magic Gold is the world’s first and only 18 carat scratch proof gold alloy, and the first result of the Hublot Metallurgy Department’s endeavors in creating revolutionary materials. « If you want something unique and different you have to create it yourself. » Sébastien Recalcati - Material Science Engineer

Carbon

Weighing half as much as aluminum yet three times stronger, carbon fiber has the highest strength to weight ratio of any material. With such unique properties, carbon fiber has replaced traditional metals and alloys in a number of applications.

Rubber

A material that is at the very core of Hublot. Soft, supple and highly resistant to wear and tear as well as being waterproof, rubber is produced naturally and artificially. The mix of both produces the desired properties for a Hublot strap.

Carbon represents approximately 18.5% of the Earth’s crust. In the design of our Hublot watches, we use carbon to obtain carbon fibre. This fibre is then woven and sheathed in resin, for use in watch cases or certain components. Carbon fibre weighs less than 2.6 g/cm3.

Design - Sketch to Prototype - At The Cutting Edge of New Ideas

It all starts by putting an idea down on paper, followed by a virtual model, and finally a prototype is built before a watch is ever manufactured. Creativity can come about in the most curious ways. From reading through the annals of history to a sudden stroke of genius while strolling through park, the sources of inspiration are endless. At the Hublot design workshop, such ideas are brought to fruition through the synergy that exists between the various experts and departments. From a sketch of a product or movement to a virtual 3D model, followed by a working prototype and finally serial production, the entire process requires patience, expertise and a lot of trial and error.

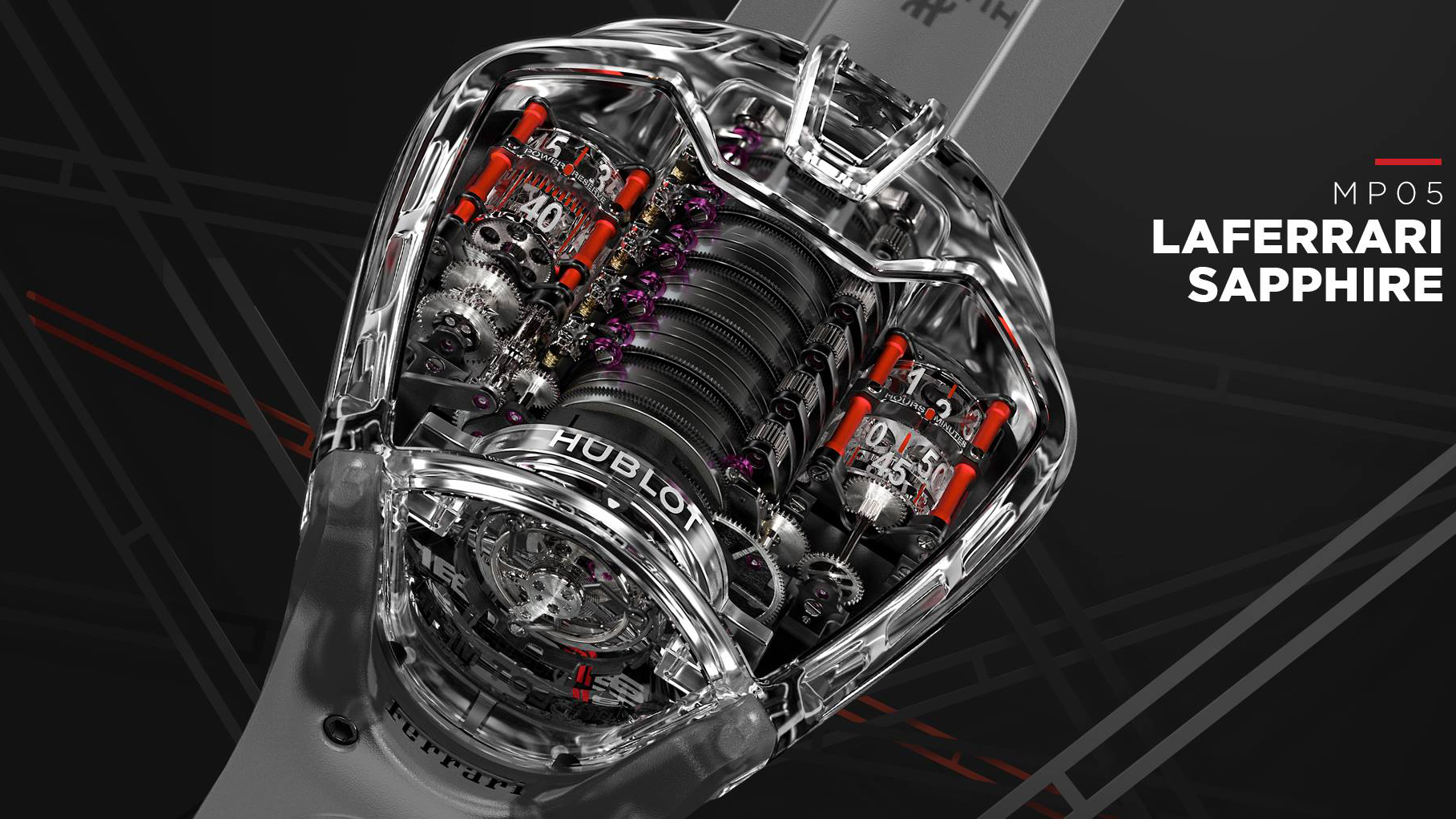

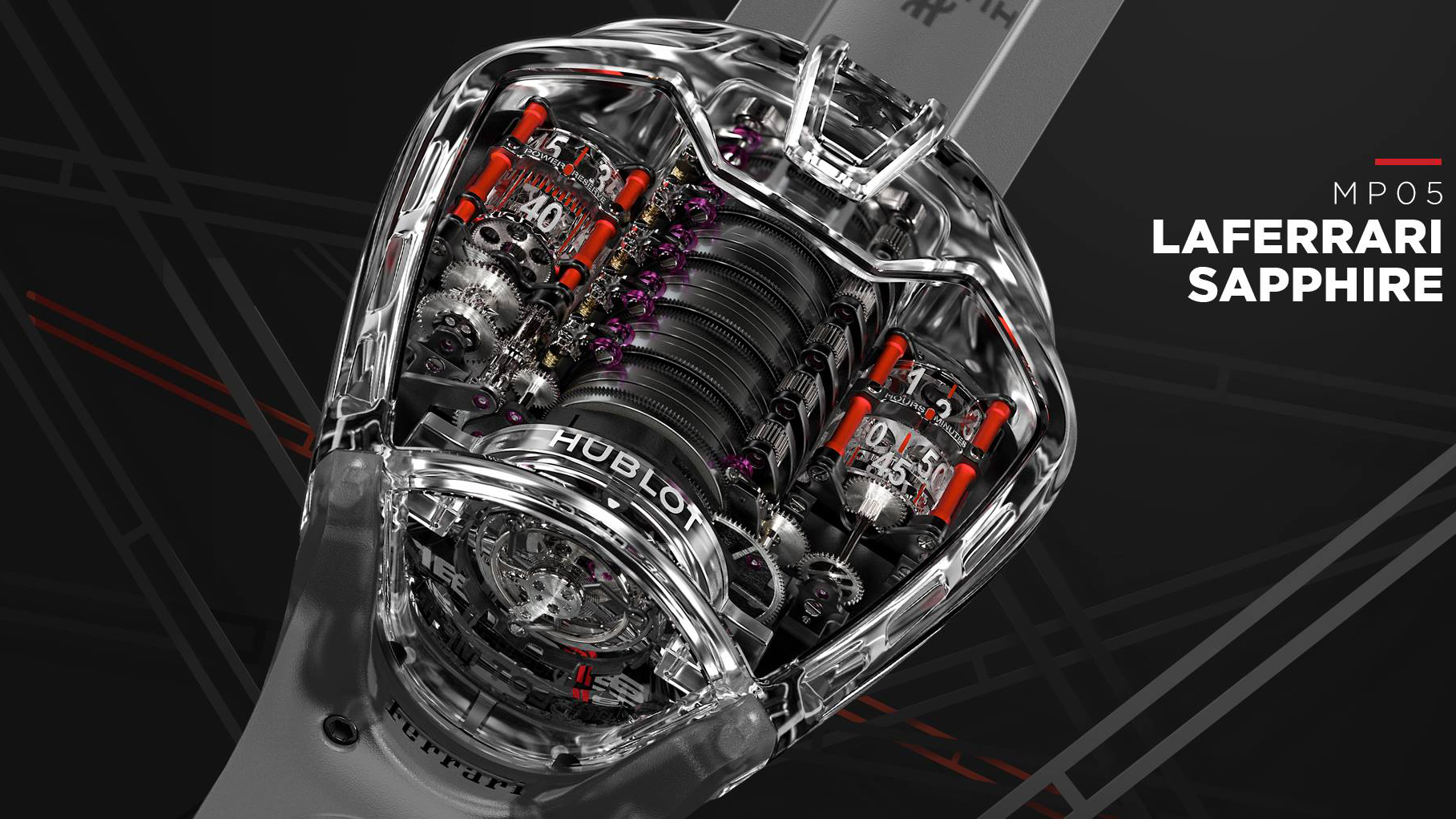

MP-05 LaFerrari

The Hublot MP-05 LaFerrari was created as a tribute to the LaFerrari, with the Hublot engineers having designed, developed, and produced the timepiece in parallel with the car. The face is made from sapphire crystal, shaped to be reminiscent of the car's outline. The case and buckle are crafted from black PVD titanium, with the strap being made from rubber.

« When Ferrari unveiled the LaFerrari, which quickly became known as one of the most spectacular vehicles ever produced by the Italian company, Hublot simultaneously launched a watch in tribute to the car, mirroring its genius. A meeting at the pinnacle of their arts. » Ricardo Guadalupe - Chief Executive Officer

The Case

“The Art of Fusion” is far more than just a slogan. It is an attitude and ideology that encompasses the very core of Hublot’s design ethos, and nowhere is this more apparent than in the case.

Evolution of The Case

The inimitable Hublot case is a work of art in its own right, a design that is constantly evolving yet true to its timeless and original silhouette. Throughout the years, Hublot has taken its original porthole design that first saw the combination of precious metals such as gold with rubber to new heights, with multi-component “sandwich” construction in a number of materials and executions. And yet every Hublot case design bears the same distinguishable trademark features including visible “H-screws”, a distinct bezel and of course a sculpted case.

Products Hublot

Hublot

Fusion in Watchmaking

Craftmanship - Introducing - The Stories Behind The Design, Innovation and Craft

Manufacture - Precision Craft - Discover The Immaculate Creation of Hublot Timepieces

A place where tradition and innovation coexist, the Hublot design workshop is a place where watchmaking is done differently, the “Art of Fusion” way.

Covering a wide range of professions and manufacturing techniques involved in the art and science of watchmaking, Hublot employs different methods of this centuries-old craft to accommodate the latest in materials and fabrication techniques as well as the most traditional forms of handwork, all under one roof. It is this flexibility in manufacturing that allows Hublot to remain at the helm of innovation in watchmaking and produce unique and cutting-edge timepieces.

« We place great value in our innovative technological manufacturing processes. » Ricardo Guadalupe - Chief Executive Officer

The Hublot design workshop possesses all the necessary know-how and infrastructure to make the future of watchmaking a reality today.

From the production of the micro-components in movements to the construction of case parts, the synergy that exists in the Hublot design workshop has allowed for such breakthrough creations as the Unico chronograph movement and proprietary materials like Magic Gold, as well as truly revolutionary designs in both case and movement construction.

Movements - In Perfect Time - Pioneers of The Most Innovative Movements

The culmination of any integrated watch manufacturer is to be able to equip its watches with exclusive movements made within its own ateliers. From self-winding chronograph movements to striking high-complication pieces and unique never-before-seen horological concepts, the traditional art of watchmaking is reinvented in a 21st century context within the walls of the Hublot manufacture.

With its own Metallurgy & Materials laboratory working closely with the Research & Development department, the possibilities for innovation are only limited by how far one’s imagination can go.

At the Hublot design workshop, such ideas of imagination are brought to fruition through the synergy that exists between the various experts and departments.

Requiring over 2 years of research and development, the in-house Unico movement is in a league of its own. Consisting of no less than 330 individually assembled components, the original Unico movement features an integrated fly back chronograph with a column-wheel mechanism positioned on the dial side of the movement.

Something of a rarity in the world of haute horlogerie. From the idea and the first pencil stroke, Hublot’s micro-technology engineers and designers put together a dossier of plans that will be used to manufacture the components of a new movement.

Materials - The Art of Fusion - Ground Breaking Innovation, Changing The World of Horology

Whether it’s improving on traditional precious metal alloys to improve their performance and aesthetics or conjuring entirely new and groundbreaking composites, the vast world of materials is at the very heart of Hublot’s “Art of Fusion” philosophy.

From traditional gold alloys to Magic Gold, from stainless steel to light and durable carbon fiber, the number of materials and possible combinations Hublot offers are truly endless.

When we talk about the use of ceramics in watch design, this does not of course mean clay-based pottery, but zirconium oxide sintered at very high temperatures. Hublot uses this high-tech ceramic, with its superior hardness and solidity, for the case and the bezel of certain watch models.

Magic Gold

Unique and proprietary to Hublot, Magic Gold is the world’s first and only 18 carat scratch proof gold alloy, and the first result of the Hublot Metallurgy Department’s endeavors in creating revolutionary materials. « If you want something unique and different you have to create it yourself. » Sébastien Recalcati - Material Science Engineer

Carbon

Weighing half as much as aluminum yet three times stronger, carbon fiber has the highest strength to weight ratio of any material. With such unique properties, carbon fiber has replaced traditional metals and alloys in a number of applications.

Rubber

A material that is at the very core of Hublot. Soft, supple and highly resistant to wear and tear as well as being waterproof, rubber is produced naturally and artificially. The mix of both produces the desired properties for a Hublot strap.

Carbon represents approximately 18.5% of the Earth’s crust. In the design of our Hublot watches, we use carbon to obtain carbon fibre. This fibre is then woven and sheathed in resin, for use in watch cases or certain components. Carbon fibre weighs less than 2.6 g/cm3.

Design - Sketch to Prototype - At The Cutting Edge of New Ideas

It all starts by putting an idea down on paper, followed by a virtual model, and finally a prototype is built before a watch is ever manufactured. Creativity can come about in the most curious ways. From reading through the annals of history to a sudden stroke of genius while strolling through park, the sources of inspiration are endless. At the Hublot design workshop, such ideas are brought to fruition through the synergy that exists between the various experts and departments. From a sketch of a product or movement to a virtual 3D model, followed by a working prototype and finally serial production, the entire process requires patience, expertise and a lot of trial and error.

MP-05 LaFerrari

The Hublot MP-05 LaFerrari was created as a tribute to the LaFerrari, with the Hublot engineers having designed, developed, and produced the timepiece in parallel with the car. The face is made from sapphire crystal, shaped to be reminiscent of the car's outline. The case and buckle are crafted from black PVD titanium, with the strap being made from rubber.

« When Ferrari unveiled the LaFerrari, which quickly became known as one of the most spectacular vehicles ever produced by the Italian company, Hublot simultaneously launched a watch in tribute to the car, mirroring its genius. A meeting at the pinnacle of their arts. » Ricardo Guadalupe - Chief Executive Officer

The Case

“The Art of Fusion” is far more than just a slogan. It is an attitude and ideology that encompasses the very core of Hublot’s design ethos, and nowhere is this more apparent than in the case.

Evolution of The Case

The inimitable Hublot case is a work of art in its own right, a design that is constantly evolving yet true to its timeless and original silhouette. Throughout the years, Hublot has taken its original porthole design that first saw the combination of precious metals such as gold with rubber to new heights, with multi-component “sandwich” construction in a number of materials and executions. And yet every Hublot case design bears the same distinguishable trademark features including visible “H-screws”, a distinct bezel and of course a sculpted case.

Products Hublot

-

Italia Independent - Hublot H008O - Gun - Hublot Official - H008O.078.075 -...

Eyeglasses with a geometric frame, handmade in Japan and embellished with iconic and precious details. Gun.

535,50 € 630,00 € -15%Reduced price ! -

Italia Independent - Hublot H008O - Grey - Hublot Official - H008O.078.000 -...

Eyeglasses with a geometric frame, handmade in Japan and embellished with iconic and precious details. Grey.

535,50 € 630,00 € -15%Reduced price ! -

Italia Independent - Hublot H008O - Silver - Hublot Official - H008O.075.000...

Eyeglasses with a geometric frame, handmade in Japan and embellished with iconic and precious details. Silver.

535,50 € 630,00 € -15%Reduced price ! -

Italia Independent - Hublot H016O - Brown - Hublot Official - H016O.092.045 -...

From a collaboration with Hublot, eyeglasses H016O were born in Italia Independent. Glasses handmade in Japan and inspired by the watches of the Swiss brand, in a perfect synthesis between tradition and modern production techniques.

331,50 € 390,00 € -15%Reduced price ! -

Italia Independent - Hublot H016O - Blue - Hublot Official - H016O.021.078 -...

From a collaboration with Hublot, eyeglasses H016O were born in Italia Independent. Glasses handmade in Japan and inspired by the watches of the Swiss brand, in a perfect synthesis between tradition and modern production techniques. Blue.

331,50 € 390,00 € -15%Reduced price ! -

Italia Independent - Hublot H016O - Black - Hublot Official - H016O.009.120 -...

From a collaboration with Hublot, eyeglasses H016O were born in Italia Independent. Glasses handmade in Japan and inspired by the watches of the Swiss brand, in a perfect synthesis between tradition and modern production techniques. Black.

331,50 € 390,00 € -15%Reduced price ! -

Italia Independent - Hublot H016O - Grey - Hublot Official - H016O.009.075 -...

From a collaboration with Hublot, eyeglasses H016O were born in Italia Independent. Glasses handmade in Japan and inspired by the watches of the Swiss brand, in a perfect synthesis between tradition and modern production techniques. Grey.

331,50 € 390,00 € -15%Reduced price ! -

Italia Independent - Hublot H010O - Gold - Hublot Official - H010O.120.092 -...

From the Light family of the 2018 Hublot and Italia Independent collection, a light and elegant round frame model: Hublot H010O.

450,50 € 530,00 € -15%Reduced price ! -

Italia Independent - Hublot H010O - Gun - Hublot Official - H010O.078.075 -...

From the Light family of the 2018 Hublot and Italia Independent collection, a light and elegant round frame model: Hublot H010O. Gun.

450,50 € 530,00 € -15%Reduced price ! -

Italia Independent - Hublot H010O - Grey - Hublot Official - H010O.078.000 -...

From the Light family of the 2018 Hublot and Italia Independent collection, a light and elegant round frame model: Hublot H010O. Grey.

450,50 € 530,00 € -15%Reduced price ! -

Italia Independent - Hublot H010O - Silver - Hublot Official - H010O.075.000...

From the Light family of the 2018 Hublot and Italia Independent collection, a light and elegant round frame model: Hublot H010O. Silver.

450,50 € 530,00 € -15%Reduced price ! -

Italia Independent - Hublot H009O - Gold - Hublot Official - H009O.120.092 -...

Designed in Italy with the Hublot "Art of Fusion" spirit, handmade in Japan with meticulousness and care. Hublot H009O is a luxury 2018 vision model, born from a collaboration between our brand and the Swiss brand Hublot.

535,50 € 630,00 € -15%Reduced price ! -

Italia Independent - Hublot H009O - Gun - Hublot Official - H009O.078.075 -...

Designed in Italy with the Hublot "Art of Fusion" spirit, handmade in Japan with meticulousness and care. Hublot H009O is a luxury 2018 vision model, born from a collaboration between our brand and the Swiss brand Hublot. Gun.

535,50 € 630,00 € -15%Reduced price ! -

Italia Independent - Hublot H009O - Grey - Hublot Official - H009O.078.000 -...

Designed in Italy with the Hublot "Art of Fusion" spirit, handmade in Japan with meticulousness and care. Hublot H009O is a luxury 2018 vision model, born from a collaboration between our brand and the Swiss brand Hublot. Gun.

535,50 € 630,00 € -15%Reduced price ! -

Italia Independent - Hublot H009O - Silver - Hublot Official - H009O.075.000...

Designed in Italy with the Hublot "Art of Fusion" spirit, handmade in Japan with meticulousness and care. Hublot H009O is a luxury 2018 vision model, born from a collaboration between our brand and the Swiss brand Hublot. Silver.

535,50 € 630,00 € -15%Reduced price ! -

Italia Independent - Hublot H011O - Gold - Hublot Official - H011O.120.092 -...

Light, sober, elegant. For this vision model from 2018 we have designed a simple and modern design, available in four color variants.

450,50 € 530,00 € -15%Reduced price ! -

Italia Independent - Hublot H011O - Gun - Hublot Official - H011O.078.075 -...

Light, sober, elegant. For this vision model from 2018 we have designed a simple and modern design, available in four color variants. Gun.

450,50 € 530,00 € -15%Reduced price ! -

Italia Independent - Hublot H011O - Grey - Hublot Official - H011O.078.000 -...

Light, sober, elegant. For this vision model from 2018 we have designed a simple and modern design, available in four color variants. Grey.

450,50 € 530,00 € -15%Reduced price ! -

Italia Independent - Hublot H011O - Silver - Hublot Official - H011O.075.000...

Light, sober, elegant. For this vision model from 2018 we have designed a simple and modern design, available in four color variants. Silver.

450,50 € 530,00 € -15%Reduced price !