No products

Categories

- Fashion Accessories

- Clothing

- Beauty & Lifestyle

-

Hi-Tech & Lifestyle

- Gaming

-

Case

- iPhone 11 Pro

- iPhone 11 Pro Max

- iPhone 11

- iPhone X / XS

- iPhone XS Max

- Samsung S10 / S10+ / S10e

- Huawei P30 / P30 Pro / P30 Lite

- Huawei P20 / P20 Pro / P20 Lite

- iPhone XR

- Samsung S9

- Samsung S9+

- iPhone 8 / 7

- iPhone 8 Plus / 7 Plus

- Samsung S8

- Samsung S8+

- Samsung S7

- Samsung S7 Edge

- iPhone 6 / 6 s

- iPhone 6 Plus / 6 s Plus

- iPhone 5 / SE

- Skin

- Audio

- Smart Home

- Drones & Hoverboard

- Photo & Video

- Desk Supplies

- Accessories

- Games

- Beverages

- Food

- Home

- Jewelry

- Luxury

- Travel

- Art

- Footwear

- Vintage Fashion

- Restaurants

- Sport

- Animals

- Gift Ideas

- Kidswear

Extra

Viewed Products

-

Cazal - Vintage 1248 - Legendary - Jade - Optical Glasses - Cazal Eyewear

Cazal sunglasses announce the release...

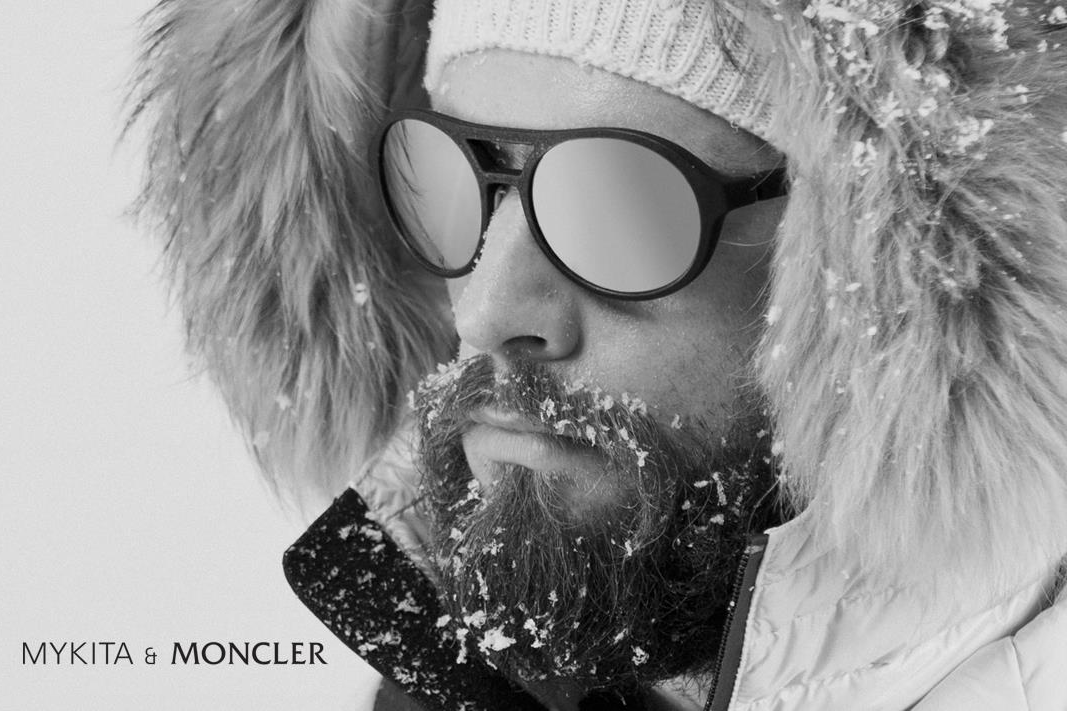

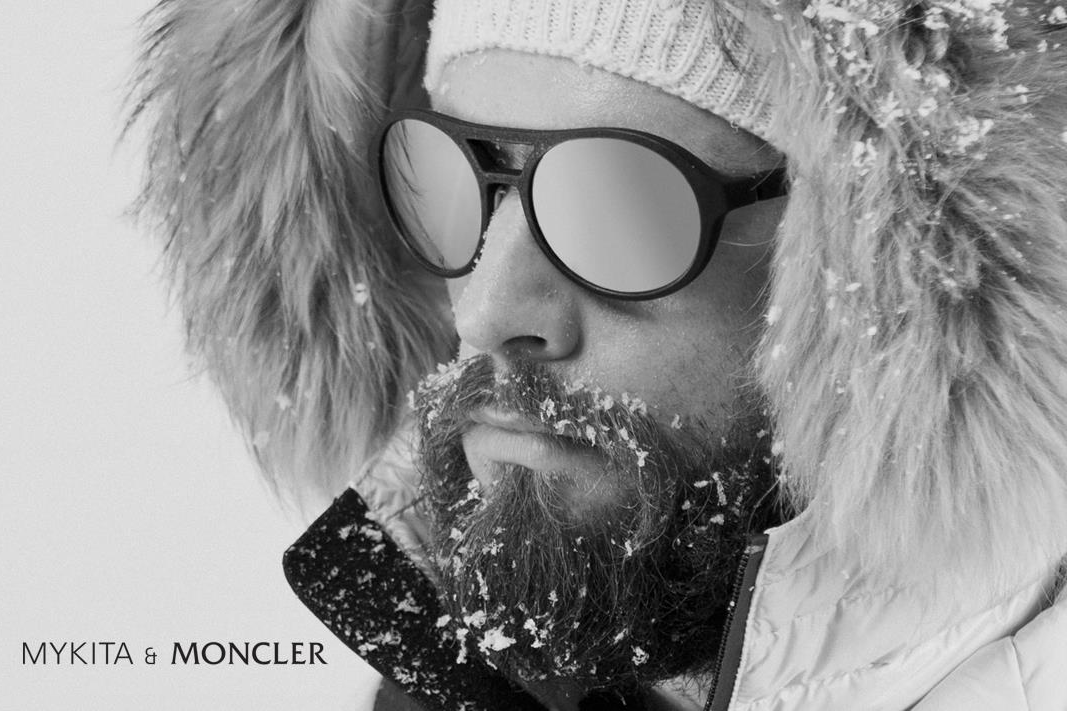

Mykita

Handmade in Berlin

History

MYKITA was founded in Berlin in 2003. Our first premises were a former children’s day care, called Kita in German. This inspired not only the name My Kita, but also the culture of curiosity, learning and play that persists to this day. Connected by our questioning of norms and conventions, we came together with the pure desire to build something of our own.

Starting out with a clear aesthetic vision, we swiftly discovered our readiness to do things ourselves. Creating an open-minded work environment and a sense of integrity toward everything in and around the product came intuitively.

A creative company in Berlin in the early 2000s did require a different mindset than it would have in London, Paris or New York – freedom from the establishment fostered self-sufficiency. MYKITA started out in the same independent and pioneering spirit that shaped our hometown.

From product to business, we have carved our own path. With no one to manufacture our original designs, the decision was made to set up the in-house production. Developing our own tools and processes to meet design requirements has since become a principle of how MYKITA operates and one of our greatest assets.

The novel design concept of the first collection introduced frames fashioned from ultra-thin stainless steel sheets. An openly displayed spiral hinge replaced the conventionally used hinge systems. This mechanical solution became an incidental styling element, a hallmark of MYKITA frames. We remain true to the fundamental design principle represented by our original patented hinge: the technical solution must also be an aesthetic one.

Globally oriented from the outset, we made our debut in Tokyo, closely followed by Paris, in 2004. The first MYKITA collection consisted of thirty superlight stainless steel glasses. The innovative product design and minimal branding immediately resonated with an international audience. Back in Berlin, we had quickly to step up the production line in order to supply the unexpected number of orders.

Connecting with a worldwide audience through our designs is a continual source of fulfilment and motivation. Official recognition regularly validates this positive customer response. Over the years MYKITA has been honoured with over 40 awards and formal distinctions in the field of product, shop, and communication design, as well as material and technological innovation, and business enterprise.

At its heart the modern manufactory is the combination of specialised craftsmanship and adapted new technologies. Routinely going beyond the traditional confines of the industry, we launched the first serially produced eyewear collection made via 3D printing technology in 2011.

Named MYKITA MYLON, the material is distinguished by our proprietary surface finishing treatment. Meanwhile, we formed longstanding collaborations with designers including Bernhard Willhelm, Damir Doma and Maison Margiela. With avant-garde forms, sophisticated colour combinations and textures, MYKITA has become an established name in international fashion.

In 2014, MYKITA settled into a historic building in the heart of Berlin Kreuzberg. Headed by founder and creative director Moritz Krueger, the team at MYKITA HAUS and worldwide is a mix of people with diverse cultural backgrounds and individual talents. Providing an environment in which these capacities can thrive collectively drives our day-to-day operations and ultimately the organic growth of the business.

About Mykita

A constant search for innovation, the visionary use of materials and a wealth of experience in eyewear design are the defining elements behind MYKITA’s collections.

A key factor in the company’s success is its holistic business philosophy, which brings together expertise from all disciplines under a single roof, the MYKITA HAUS.

It thrives on the power of a self-contained network that enables interdisciplinary research and the transfer of technologies.

This all-encompassing mentality is also reflected in the MYKITA Shops.

The unique retail concept unites the firm’s own design principles with optical precision made in Germany.

MYKITA’s eyewear collections are available at the firm’s own shops in Berlin, Paris, New York, Los Angeles, Washington, Copenhagen, Monterrey, Cartagena, Zurich, Zermatt, Vienna and Tokyo as well as at selected opticians and fashion outlets in over 80 countries.

Mykita Shop Concept

The unique shop architecture – developed by MYKITA itself – is based on the progressive composition of different room elements and contrasting materials. It is a marriage of ready-made objects removed from their original context, combined with purpose-designed furniture and a stage-like lighting concept. The result is an art installation with a bold and minimal construction that retains the original character of the locations.

The primary design element of the shop interior is the all-white MYKITA Wall. It comprises perforated steel angle beads that are reinvented from their regular function as heavy-duty shelving supports. The resulting structure is backlit and serves as a presentation and display area.

Individual shelf elements inserted into the wall provide each model with its own little stage. In addition, out-of-service flight attendant trolleys that have circled the globe a thousand times are given a new lease of life here as a storage facility.

MYKITA’s holistic business philosophy, which brings together expertise from all disciplines under a single roof, is also reflected in the MYKITA Shops. In-house optometrists perform certified eye tests, generate customised optical profiles and adapt the frame and lenses to the wearer’s face.

The ”Relaxed Vision Center” integrated into the shops – a specialist lab equipped with state-of-the-art precision instruments from Carl Zeiss research – embodies the company’s holistic approach to design and quality.

MYKITA has its own shops in Berlin, Paris, New York, Copenhagen, Monterrey, Cartagena, Zurich, Zermatt, Vienna and Tokyo. The brand’s eyewear collections are in addition stocked by selected opticians and fashion stores in over 70 countries.

Modern Manufactory

Welcome to the modern manufactory. In addition to providing a behind-the-scenes look at life and work in the building, the photos also portray the entire in-house production cycle.

Design Awards

MYKITA eyewear collections have won a variety of design awards since the company was founded in 2003. That doesn’t just apply to the products themselves; the annual campaign, the MYKITA 8 anniversary book and the MYKITA MYLON campaign have likewise all won accolades.

Products Mykita

Mykita

Handmade in Berlin

History

MYKITA was founded in Berlin in 2003. Our first premises were a former children’s day care, called Kita in German. This inspired not only the name My Kita, but also the culture of curiosity, learning and play that persists to this day. Connected by our questioning of norms and conventions, we came together with the pure desire to build something of our own.

Starting out with a clear aesthetic vision, we swiftly discovered our readiness to do things ourselves. Creating an open-minded work environment and a sense of integrity toward everything in and around the product came intuitively.

A creative company in Berlin in the early 2000s did require a different mindset than it would have in London, Paris or New York – freedom from the establishment fostered self-sufficiency. MYKITA started out in the same independent and pioneering spirit that shaped our hometown.

From product to business, we have carved our own path. With no one to manufacture our original designs, the decision was made to set up the in-house production. Developing our own tools and processes to meet design requirements has since become a principle of how MYKITA operates and one of our greatest assets.

The novel design concept of the first collection introduced frames fashioned from ultra-thin stainless steel sheets. An openly displayed spiral hinge replaced the conventionally used hinge systems. This mechanical solution became an incidental styling element, a hallmark of MYKITA frames. We remain true to the fundamental design principle represented by our original patented hinge: the technical solution must also be an aesthetic one.

Globally oriented from the outset, we made our debut in Tokyo, closely followed by Paris, in 2004. The first MYKITA collection consisted of thirty superlight stainless steel glasses. The innovative product design and minimal branding immediately resonated with an international audience. Back in Berlin, we had quickly to step up the production line in order to supply the unexpected number of orders.

Connecting with a worldwide audience through our designs is a continual source of fulfilment and motivation. Official recognition regularly validates this positive customer response. Over the years MYKITA has been honoured with over 40 awards and formal distinctions in the field of product, shop, and communication design, as well as material and technological innovation, and business enterprise.

At its heart the modern manufactory is the combination of specialised craftsmanship and adapted new technologies. Routinely going beyond the traditional confines of the industry, we launched the first serially produced eyewear collection made via 3D printing technology in 2011.

Named MYKITA MYLON, the material is distinguished by our proprietary surface finishing treatment. Meanwhile, we formed longstanding collaborations with designers including Bernhard Willhelm, Damir Doma and Maison Margiela. With avant-garde forms, sophisticated colour combinations and textures, MYKITA has become an established name in international fashion.

In 2014, MYKITA settled into a historic building in the heart of Berlin Kreuzberg. Headed by founder and creative director Moritz Krueger, the team at MYKITA HAUS and worldwide is a mix of people with diverse cultural backgrounds and individual talents. Providing an environment in which these capacities can thrive collectively drives our day-to-day operations and ultimately the organic growth of the business.

About Mykita

A constant search for innovation, the visionary use of materials and a wealth of experience in eyewear design are the defining elements behind MYKITA’s collections.

A key factor in the company’s success is its holistic business philosophy, which brings together expertise from all disciplines under a single roof, the MYKITA HAUS.

It thrives on the power of a self-contained network that enables interdisciplinary research and the transfer of technologies.

This all-encompassing mentality is also reflected in the MYKITA Shops.

The unique retail concept unites the firm’s own design principles with optical precision made in Germany.

MYKITA’s eyewear collections are available at the firm’s own shops in Berlin, Paris, New York, Los Angeles, Washington, Copenhagen, Monterrey, Cartagena, Zurich, Zermatt, Vienna and Tokyo as well as at selected opticians and fashion outlets in over 80 countries.

Mykita Shop Concept

The unique shop architecture – developed by MYKITA itself – is based on the progressive composition of different room elements and contrasting materials. It is a marriage of ready-made objects removed from their original context, combined with purpose-designed furniture and a stage-like lighting concept. The result is an art installation with a bold and minimal construction that retains the original character of the locations.

The primary design element of the shop interior is the all-white MYKITA Wall. It comprises perforated steel angle beads that are reinvented from their regular function as heavy-duty shelving supports. The resulting structure is backlit and serves as a presentation and display area.

Individual shelf elements inserted into the wall provide each model with its own little stage. In addition, out-of-service flight attendant trolleys that have circled the globe a thousand times are given a new lease of life here as a storage facility.

MYKITA’s holistic business philosophy, which brings together expertise from all disciplines under a single roof, is also reflected in the MYKITA Shops. In-house optometrists perform certified eye tests, generate customised optical profiles and adapt the frame and lenses to the wearer’s face.

The ”Relaxed Vision Center” integrated into the shops – a specialist lab equipped with state-of-the-art precision instruments from Carl Zeiss research – embodies the company’s holistic approach to design and quality.

MYKITA has its own shops in Berlin, Paris, New York, Copenhagen, Monterrey, Cartagena, Zurich, Zermatt, Vienna and Tokyo. The brand’s eyewear collections are in addition stocked by selected opticians and fashion stores in over 70 countries.

Modern Manufactory

Welcome to the modern manufactory. In addition to providing a behind-the-scenes look at life and work in the building, the photos also portray the entire in-house production cycle.

Design Awards

MYKITA eyewear collections have won a variety of design awards since the company was founded in 2003. That doesn’t just apply to the products themselves; the annual campaign, the MYKITA 8 anniversary book and the MYKITA MYLON campaign have likewise all won accolades.

Products Mykita

-

Mykita - Lamin - Acetate - Taupe Shiny Silver - Acetate Glasses - Optical...

Warm and comfortable on the skin, acetate offers an extensive array of colour options. The wide range of acetate and mixed material models in monochrome, translucent or patterned colourways by MYKITA are hand-assembled at the modern manufactory in Berlin.

488,75 € 575,00 € -15%Reduced price ! -

Mykita - Musk - Mylon - Pitch Black - Mylon Glasses - Optical Glasses -...

Made of MYLON – an exceptionally light and durable material – MUSK in MD1 Pitch Black with Dark Grey Solid lenses is a square shaped sunglass frame from the MYKITA MYLON collection. Handcrafted in Berlin.

395,25 € 465,00 € -15%Reduced price ! -

Mykita - Musk - Mylon - Slate Grey - Mylon Glasses - Optical Glasses - Mykita...

Made of MYLON – an exceptionally light and durable material – MUSK in MD1 Pitch Black with Dark Grey Solid lenses is a square shaped sunglass frame from the MYKITA MYLON collection. Handcrafted in Berlin.

395,25 € 465,00 € -15%Reduced price ! -

Mykita - Gia - Decades - Shiny Silver Black Cool Grey - Metal Collection -...

Classic panto shapes of the Thirties, strong lines of the Sixties or the oversize forms of the Seventies and Eighties – the DECADES collection interprets historical eyewear styles for the here and now. The distinctive aesthetic of the models stems from the translation of classic forms into a modern MYKITA construction.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Leeland - Decades - Shiny Silver Black Cool Grey - Metal Collection...

Classic panto shapes of the Thirties, strong lines of the Sixties or the oversize forms of the Seventies and Eighties – the DECADES collection interprets historical eyewear styles for the here and now. The distinctive aesthetic of the models stems from the translation of classic forms into a modern MYKITA construction.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Pearl - Decades - Champagne Gold Zanzibar Cedar Brown - Metal...

Classic panto shapes of the Thirties, strong lines of the Sixties or the oversize forms of the Seventies and Eighties – the DECADES collection interprets historical eyewear styles for the here and now. The distinctive aesthetic of the models stems from the translation of classic forms into a modern MYKITA construction.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Dakar - Mykita Acetate - Maroon Shiny Silver Cruxite Brown - Acetate...

This sunglasses frame from the MYKITA ACETATE collection has been responsibly designed and crafted from sustainable Acetate Renew. The timeless aesthetics, patented design innovation and highest quality standards ensure the longevity of the product. Handmade in Berlin.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Dakar - Mykita Acetate - Chilled Raw Black Havana Silver Dark Grey -...

This sunglasses frame from the MYKITA ACETATE collection has been responsibly designed and crafted from sustainable Acetate Renew. The timeless aesthetics, patented design innovation and highest quality standards ensure the longevity of the product. Handmade in Berlin.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Lome - Mykita Acetate - Clear Ash Shiny Silver Euphosgreen - Acetate...

This sunglasses frame from the MYKITA ACETATE collection has been responsibly designed and crafted from sustainable Acetate Renew. The timeless aesthetics, patented design innovation and highest quality standards ensure the longevity of the product. Handmade in Berlin.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Eli - NO1 - Indigo Dark Sand Polarized Pro Hi-Con Grey - Metal...

Made of lightweight stainless steel, ELI in Indigo/Dark Sand with Polarised Pro Hi Con Grey lenses is a square shaped sunglass frame from the MYKITA NO1 collection. Handcrafted in Berlin.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Perry - NO1 - Black White PolPro Hi-Con Brown Silver Flash - Metal...

Made of lightweight stainless steel, PERRY in Black/White with Polarised Pro Hi Con Brown Silver Flash lenses is a square shaped sunglass frame from the MYKITA NO1 collection. Handcrafted in Berlin.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Eli - NO1 - Matte Silver Black Polarized Pro Green - Metal...

Made of lightweight stainless steel, ELI in Matte Silver/Black with Polarised Pro Green lenses is a square shaped sunglass frame from the MYKITA NO1 collection. Handcrafted in Berlin

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Garland - Decades - Deep Purple - Metal Glasses - Optical Glasses -...

Classic panto shapes of the Thirties, strong lines of the Sixties or the oversize forms of the Seventies and Eighties – the DECADES collection interprets historical eyewear styles for the here and now. The distinctive aesthetic of the models stems from the translation of classic forms into a modern MYKITA construction.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Eli - NO1 - Storm Grey Black Polarized Pro Grey - Metal Collection -...

Made of lightweight stainless steel, ELI in Storm Grey/Black with Polarised Pro Hi Con Grey lenses is a square shaped sunglass frame from the MYKITA NO1 collection. Handcrafted in Berlin.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Leon - Decades - Black - Metal Glasses - Optical Glasses - Mykita...

Classic panto shapes of the Thirties, strong lines of the Sixties or the oversize forms of the Seventies and Eighties – the DECADES collection interprets historical eyewear styles for the here and now. The distinctive aesthetic of the models stems from the translation of classic forms into a modern MYKITA construction.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Perry - NO1 - Indigo Dark Sand Polarized Pro Hi-Con Grey - Metal...

Made of lightweight stainless steel, PERRY in Indigo/Dark Sand with Polarised Pro Hi Con Grey lenses is a square shaped sunglass frame from the MYKITA NO1 collection. Handcrafted in Berlin.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Leon - Decades - Elderberry - Metal Glasses - Optical Glasses -...

Classic panto shapes of the Thirties, strong lines of the Sixties or the oversize forms of the Seventies and Eighties – the DECADES collection interprets historical eyewear styles for the here and now. The distinctive aesthetic of the models stems from the translation of classic forms into a modern MYKITA construction.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Perry - NO1 - Matte Silver Black Polarized Pro Green - Metal...

Made of lightweight stainless steel, PERRY in Matte Silver/Black with Polarised Pro Green 15 lenses is a square shaped sunglass frame from the MYKITA NO1 collection. Handcrafted in Berlin.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Leon - Decades - Indigo - Metal Glasses - Optical Glasses - Mykita...

Classic panto shapes of the Thirties, strong lines of the Sixties or the oversize forms of the Seventies and Eighties – the DECADES collection interprets historical eyewear styles for the here and now. The distinctive aesthetic of the models stems from the translation of classic forms into a modern MYKITA construction.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Waters - Decades - Lagoon Green - Metal Glasses - Optical Glasses -...

Classic panto shapes of the Thirties, strong lines of the Sixties or the oversize forms of the Seventies and Eighties – the DECADES collection interprets historical eyewear styles for the here and now. The distinctive aesthetic of the models stems from the translation of classic forms into a modern MYKITA construction.

420,75 € 495,00 € -15%Reduced price ! -

Mykita - Ahti - Lite - Maroon Shiny Graphite - Acetate Glasses - Optical...

This optical frame from the LITE collection has been responsibly designed and crafted from circular materials. The reduced design concept stands for supreme comfort in a refined aesthetic. Handmade in Berlin.

437,75 € 515,00 € -15%Reduced price !